How Do You Coordinate Earth Leakage Protection With Variable Frequency Drives and Long Cable Runs in Mining MCCs Without Nuisance Trips?

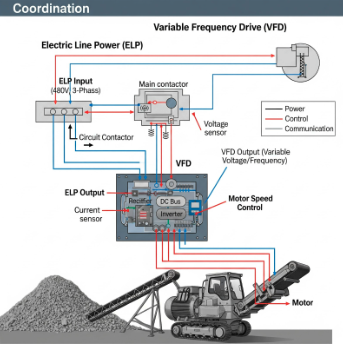

Mining MCCs rely heavily on VFD driven motors for conveyors, crushers, slurry pumps, and ventilation systems. These drives improve efficiency and control, yet they introduce high frequency leakage, cable capacitance effects, and EMC noise that make earth leakage protection more sensitive. If settings are not coordinated correctly, VFDs can trigger nuisance EL trips that stall production, interrupt conveyor sequences, and create costly downtime.

This Q&A guide explains how to coordinate earth leakage protection in VFD applications using practical, field proven engineering steps. It is written for mining plant engineers, MCC specialists, control technicians, and reliability leads who require selective tripping, safe operation, and stable uptime. Settings that appear below are indicative and must always be verified on site through injection tests, OEM data, and commissioning procedures.

You can learn more about upstream coordination and relay behaviour in the MA Relay Deep Dive and compare EL compatible relays in the Mining Product Comparison. If you prefer relay recommendations filtered by current range and mounting, try our Relay Selector tool.

Why do VFDs and long cable runs increase earth leakage and trip risk in mining MCCs?

VFDs generate high switching frequencies that travel through the motor cable insulation and return through earth. This creates steady state and transient leakage that does not represent a fault but can exceed the trip threshold of standard earth leakage devices. The effect becomes more pronounced in mining installations because MCCs often sit 100 to 200 metres away from field motors.

Key contributors to leakage

-

PWM switching creates high frequency components that flow through parasitic capacitance.

-

Long cable runs add capacitance to earth and amplify leakage.

-

Multiple VFDs connected to a shared upstream EL device create cumulative leakage.

-

Incorrect grounding or shared neutrals increase unwanted earth currents.

-

EMC noise from nearby conveyors and crushers can appear as residual current.

Practical example: If a 110 kW conveyor VFD sits 150 metres from its motor, the combined capacitance of the cable, drive filter, and motor can easily produce more than 150 to 250 mA of leakage even when running normally.

Engineering implication: Standard 30 mA or 100 mA devices are guaranteed to nuisance trip. Sites need VFD compatible earth leakage relays, wider current ranges, programmable curves, and commissioning tests to measure real leakage before setting thresholds.

What settings should engineers use for earth leakage thresholds and delays on VFD driven feeders?

Mining sites require sensitive protection, but not at the cost of plant shutdowns. The goal is simple. Set the trip level high enough to ignore harmless VFD leakage yet low enough to detect genuine insulation faults.

Indicative settings for VFD feeders

-

Trip threshold typically begins around 100 to 300 mA depending on drive size and cable length. Always measure each feeder’s steady state leakage during commissioning.

-

Time delay should ride through the drive’s transient leakage during acceleration. Typical delays are tens to a few hundred milliseconds but must be coordinated with upstream relays.

-

Ramp coordination increases delay as circuits increase in rating to ensure upstream selectivity.

-

Verification always confirm settings with injection tests and a simulated start under load.

Recommended devices: Use Type B or VFD compatible earth leakage relays capable of detecting DC and high frequency leakage.

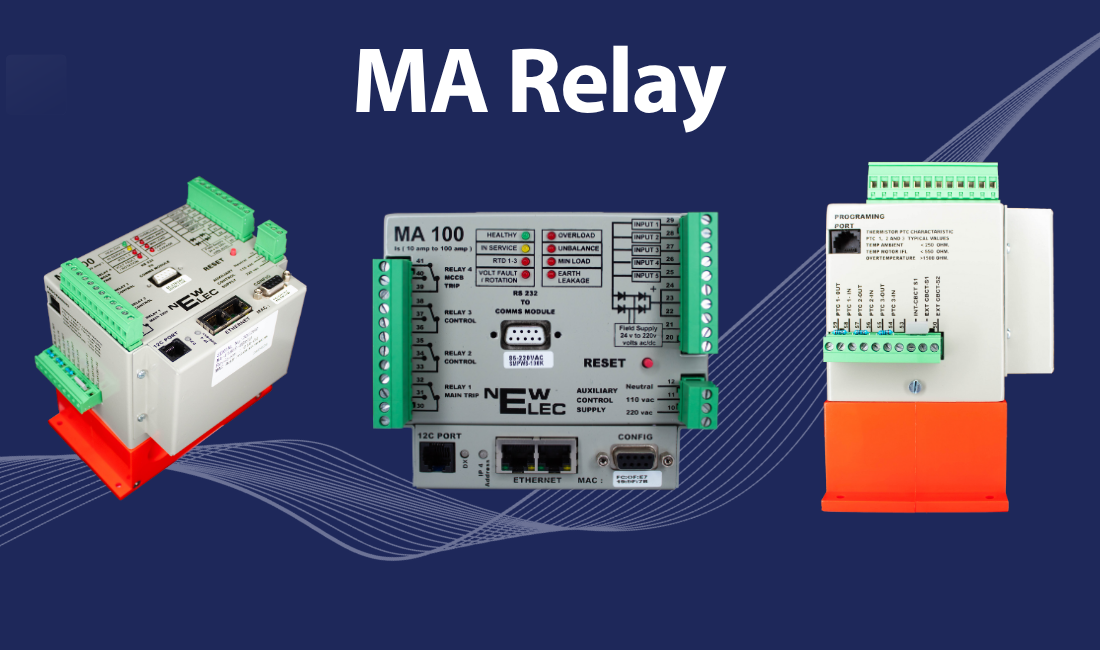

NewElec’s MA Relay is designed with programmable curves and differential sensing that suit mining environments. Learn more about programmable trip curves in the MA Relay Deep Dive.

Why Zoning Prevents Cascading Trips

If 15 feeders share one upstream earth leakage device, the combined steady leakage can exceed 150 to 300 mA even when everything is healthy. One transient can trip the entire bank. Zoning isolates the problem and protects uptime. See how start supervision interacts with EL delays in the MA Relay Product Guide.

How do engineers coordinate earth leakage protection with motor relays and MCC zoning?

Selective tripping is vital in mining. If one conveyor or crusher feeder experiences a fault, the entire MCC should not lose power. Proper zoning ensures that only the affected circuit trips while upstream zones remain stable.

Zoning Guidelines:

- Provide individual EL relays per motor circuit or per MCC zone.

- Use differential EL protection within each zone and a higher threshold upstream.

- Integrate EL feedback into the motor protection relay for unified reporting.

- Ensure thermal protection and start supervision remain valid despite EL delays.

- Avoid feeding multiple VFDs from a single EL device because cumulative leakage distorts selectivity.

How do long cable runs, EMC noise, and grounding errors affect EL coordination?

Long cable runs are unavoidable in mining conveyors, dewatering pumps, ventilation fans, and crushers. These distances increase cable capacitance, which increases harmless leakage. They also introduce EMC noise that interacts with the EL relay.

Engineering Considerations

-

Use screened or armoured cables with symmetrical earth returns.

-

Terminate shields correctly at both ends unless site standards specify single point bonding.

-

Install EMC filters such as common mode chokes or sine filters on the VFD output.

-

Ensure earthing points are low resistance and inspected regularly.

-

Route signal cables away from VFD output cables to prevent induced current.

-

Avoid mixed cable trays for noisy and sensitive circuits.

Risk from EMI

EMI can mimic leakage and trigger a false trip if the EL relay cannot distinguish between high frequency noise and true residual current. VFD compatible devices with filtering and programmable curves are essential.

Compare EL and EMI tolerance by model in the Mining Product Comparison.

What power quality issues upstream can trigger earth leakage nuisance trips?

Even if the EL relay is perfectly set, poor upstream power quality can cause spurious trips. VFDs are sensitive to harmonics and voltage imbalance, which in turn can distort current flow and create unexpected residual currents.

Power quality checks to include

-

Phase voltage imbalance should be below two percent.

-

Maintain total harmonic distortion below five percent.

-

Inspect for stray currents caused by shared neutrals.

-

Verify the stability of the supply during large simultaneous starts.

-

Use relays with power quality monitoring such as NewElec’s KD Feeder Protection range.

Why PQ matters

Harmonics can create distorted waveforms that confuse basic EL relays. Voltage dips during crusher or conveyor startup can spike leakage values. Stable PQ improves the accuracy of EL protection and protects drives, motors, and relays from premature failure.

What commissioning steps and pitfalls must engineers manage to prevent nuisance trips?

A structured commissioning process eliminates most nuisance trip problems. The goal is to measure, test, and record real leakage values before setting final thresholds.

Commissioning checklist

-

Verify cable lengths and insulation resistance for each feeder.

-

Confirm filters, reactors, or chokes are installed as designed.

-

Measure steady state leakage during run and acceleration.

-

Set EL thresholds at least fifty percent above measured leakage.

-

Coordinate time delays by zone.

-

Perform current injection tests for each relay.

-

Validate CT orientation for differential EL devices.

-

Record baseline leakage values for future maintenance comparison.

-

Confirm PQ stability under load and during simultaneous starts.

Common pitfalls

-

Shared neutral or earth bars between MCC sections.

-

Using factory default EL settings without measurement.

-

Ignoring leakage data provided by the VFD manufacturer.

-

Skipping re testing after motor or cable replacement.

-

Installing VFDs on feeders with legacy EL devices not rated for high frequency leakage.

Refer to the Relay Selector to filter EL compatible relays rated for VFD installations.

Applied Engineering Scenarios

Scenario 1. VFD conveyor with 150 m cable run

A 90 kW conveyor motor is powered by a VFD located 150 metres from the field motor.

Measured values

Run up leakage: 180 mA

Steady leakage: 120 mA

Indicative setup

EL trip threshold: 300 mA

Delay: 200 ms

Individual EL relay on feeder with upstream 500 mA delay

Verified with injection and live start tests

The result is selective tripping where harmless capacitance based leakage is ignored while genuine faults still trip quickly.

Scenario 2. Crusher with soft starter and long cable

A 250 kW crusher uses a soft starter rather than a VFD but has a long feed cable and multiple earths. High inertia starts produce leakage spikes that trip the upstream EL device.

Solution

-

Increase delay at feeder to about 300 ms

-

Use time grading across MCC zones

-

Add thermal supervision using the motor relay

-

Test starts under load before commissioning

This prevents the entire crusher bay from tripping during routine startup.

Frequently Asked Questions Recap

Does a VFD always increase EL trip risk?

Yes. VFD switching always generates leakage. The magnitude depends on drive size, switching frequency, cable length, and grounding quality. Using VFD compatible EL relays prevents nuisance trips.

How do long cable runs change EL settings?

Longer cables increase capacitance which increases steady leakage. Trip thresholds must be set above measured leakage and verified with injection tests.

What protection features do NewElec relays provide?

The relays include thermal overload protection (class 3 to 35), overcurrent, unbalanced current sensing, breaker-failure detection, earth leakage/fault protection, and short circuit trip capabilities.

When should upstream EL be time delayed?

Delays ensure selective tripping. Upstream devices should have higher thresholds and longer delays to allow downstream feeders to operate first.

Can PQ issues appear as EL faults?

Yes. Harmonics, dips, and imbalance distort current flow and create false earth currents that may trip sensitive devices.

Why Choose NewElec?

- Feature-Rich Products – Our relays come equipped with advanced functionalities, including real-time event recording and seamless integration with various communication protocols. These features provide comprehensive protection and control, setting NewElec apart from competitors.

- Long-Term Durability – Designed for a lifespan of 20 to 30 years, NewElec’s products offer long-term reliability and reduced maintenance costs. This durability ensures a solid return on investment and uninterrupted operations.

- Exceptional Support – Our dedicated team provides ongoing guidance and assistance, from initial consultation to post-implementation support. We work closely with clients to tailor solutions that meet their specific needs, ensuring a seamless integration process and optimal performance.

Don’t wait for a shutdown or system failure to upgrade. Why Wait to Automate™ is your practical, scalable, and affordable path to intelligent motor protection and automation. Contact us today to learn how easy it is to bring your MCC into the digital age.