Ensure Safety and Continuity in the Petrochemical, Oil & Gas Industry with Advanced Motor Protection and Control Solutions.

Safety, reliability, and operational uptime are critical across the Petrochemical, Oil & Gas industry. These environments demand robust electrical infrastructure to power essential systems such as pumps, compressors, fans, cranes, and cooling units. NewElec’s advanced motor and relay protection solutions ensure that your operations remain uninterrupted while maintaining full compliance with industry safety standards.

Our KD, KE and NewCode relays provide intelligent protection for a wide range of applications. In pumping operations, whether chemical dosing, brine injection, or crude oil transfer, NewElec relays safeguard motor systems from thermal overload, locked rotor, running stall, dry run, earth leakage and short-circuit. High inertia start protection for fan motors in cooling towers and flare stacks. Crane systems handling drums and hazardous loads benefit from torque-sensitive relays that prevent overload and ensure safe operation. Pipeline motor stations to gas boosting compressors and additive blending pumps, NewElec relays deliver precise, real-time monitoring and motor diagnostics.

Why Wait to Automate™

NewElec is leading automation in hazardous industries with up to 32 NewCode relays communicating directly with your PLC. Our newest protocols, including Modbus-TCP, PROFINET, and allow seamless control integration.

Contact NewElec Today

Comprehensive Protection and Long-Term Value

From upstream drilling operations to downstream refining and distribution, the Petrochemical and Oil & Gas industry depends on uninterrupted electrical performance. NewElec’s solutions are engineered for long-term durability and resilience in corrosive, vibration-heavy, and temperature-volatile environments. Our protection relays deliver long-lasting value and reduce the risk of premature equipment failure.

Our intelligent relays offer continuous monitoring, helping engineers detect and address irregular motor conditions before they escalate into downtime or safety incidents. With the ability to integrate into existing plant automation infrastructure, these solutions allow for smarter, data-driven maintenance planning and reduced total cost of ownership.

By combining rugged construction with digital communication capabilities, NewElec ensures that even the most remote and challenging applications—such as chemical loading bays and unmanned booster stations—benefit from robust, scalable, and field-proven protection technology.

“Quiet Champion” In the Industry

Advanced Earth Leakage and Earth Fault Protection solutions

Integration Ready (Modbus/PROFINET)

Immune to Harmonics

IP65 Rated for Harsh Environments

Highest standards of safety and reliability

Coverage for conveyors, fans, crusher motors, Compressors, and pumps

Configurable for Mixed & Radial Flow Pumps

Compatible with VSD and Submersible Systems

30 Year Lifespan

Explore Our Motor Protection Relay Solutions for Oil & Gas Plants

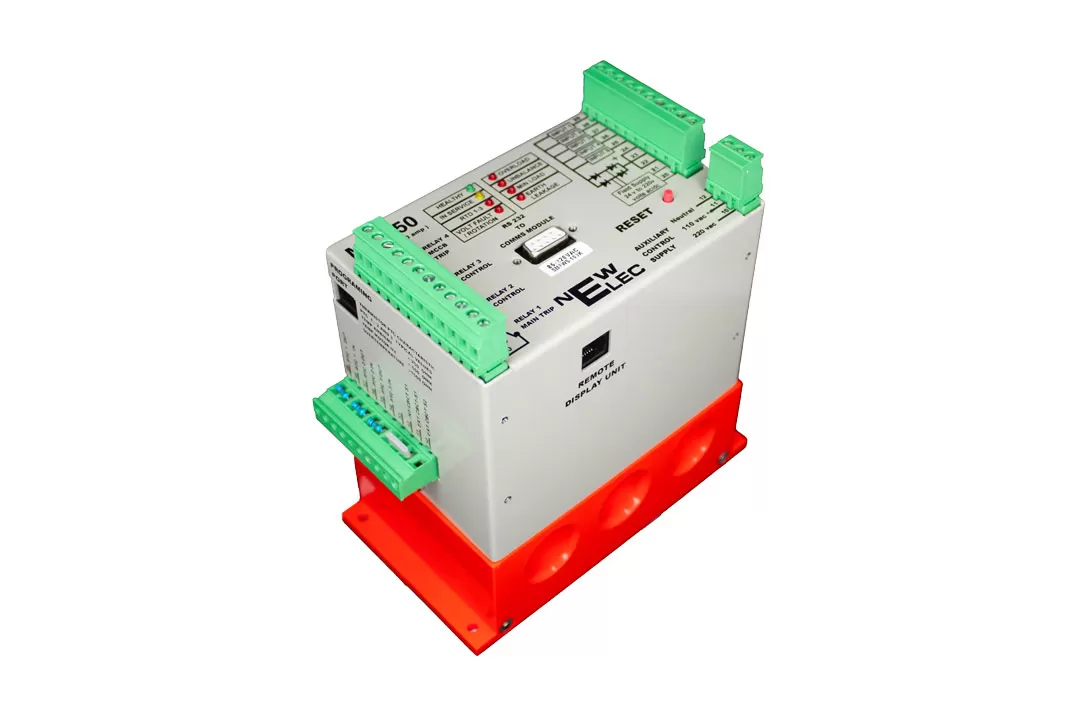

Product – NewCode Relay

Product - MA Series Relays

Product – KE Series Relay

Product - KD Series Relay

Product – 330 Series Relay

Product - 320-327 Series Relay

Product - GA Earth Leakage Relay

Product - GA Plus Relay

Why Choose NewElec for Your Protection and Control Relays

Choose NewElec for state-of-the-art Switchgear solutions tailored to your needs, backed by technical and functional expertise. Our range of motor protection relays, Earth Leakage Protection Relays, and Integration ready solutions enhance your operations and offer insight on motor health and performance. We offer feature-rich products with a 20 to 30-year lifespan.

Innovation drives us at NewElec. We develop products that push boundaries and meet future needs. Our commitment to innovation, quality, and customer support ensures reliable solutions when you need them.

Feature-Rich Product:

Known as the “Best Kept Secret” in the market, our products offer a wide range of features that set them apart from the competition.

Long Lifespan:

Designed for a 20 to 30-year lifespan, our products reduce long-term costs and provide lasting value.

Liability Management

We offer guidance and support to help you manage liability risks without creating additional issues.

Knowledge Source:

Positioned as a valuable source of industry knowledge and information, we provide our customers with remote or on-site support they need to succeed.

Event and Fault Records:

Time-stamped and exportable event and fault record capabilities help you monitor and manage your operations more effectively.

Comprehensive Protection:

Our products include free Front-End Software for low/medium voltage motor-driven applications, ensuring that your operations are safe and reliable.

Commitment to Quality:

At NewElec, quality is our top priority. We are committed to providing products that meet the highest standards of safety and reliability. Our rigorous testing and quality control processes ensure that every product we produce is of the highest quality, providing you with the confidence you need to trust our solutions.

Customer Support:

Our relationship with customers extends beyond the sale, contributing to our high level of client retention. We offer ongoing support and assistance to ensure that our products continue to meet your needs. Our team of experts are always available to provide guidance and support, helping you maximise the benefits of our products.

Exceptional Support and Industry Expertise

With decades of experience supporting industrial motor control in some of the most hazardous environments, NewElec brings trusted expertise to every project. From new builds to retrofits, our team partners with you to deliver dependable, compliant, and efficient relay protection tailored to your unique operational demands.

Transform Your Operations with Motor Protection Relays from NewElec

At NewElec, we are proud of our history and excited about our future. We invite you to join us on our journey as we continue to lead the way in Motor Protection solutions. Partner with us to access cutting-edge products and exceptional service tailored to your needs. Our offerings include advanced Motor Protection Relays, Earth Leakage Relays, Feeder Protection Relays, and Power Quality Monitoring Relays.

Contact us today to learn more about how NewElec can support your mining or plant operations and enhance your efficiency while protecting your switchgear and drives.

Which types of motor-driven equipment in oil & gas operations can your relays protect?

NewElec relays protect motors used in pumps (e.g. chemical dosing, crude oil transfer, brine injection), compressors, fans (e.g. cooling towers, flare stacks), cranes, loading/unloading systems, and pipelines.

What fault or hazardous conditions do your relays detect and respond to?

They guard against thermal overload, locked rotor / stalled motor, dry run, phase loss / single phasing, earth leakage / insulation faults, and short-circuits.

Can your protection solutions integrate with existing industrial automation systems (PLCs, SCADA)?

Yes. The relays communicate via protocols such as Modbus-TCP and PROFINET, enabling direct integration with PLCs and higher-level control/SCADA systems.

Are your relays rugged enough to operate reliably in harsh, hazardous environments?

How do your relays support long-term maintenance and diagnostics?

The relays offer time-stamped event and fault logging (exportable), continuous monitoring of motor health, and remote configuration support to help with predictive maintenance and reducing downtime.