Modernise Without Overhauling. Improve Without Disrupting.

Improve Uptime. Extend Equipment Life. Make Smarter Decisions.

NewElec bridges that gap—helping industrial teams:

- Access real-time data without replacing MCCs or overhauling wiring.

- Receive early alerts for mechanical and electrical faults.

- Delay costly system replacements by improving performance of current assets.

- Enable data-driven maintenance decisions for improved productivity and cost control.

NewElec helps you unlock real-time operational visibility and smarter fault management—at a fraction of the cost—by getting the most value out of the equipment you already have rather than outlaying the capital for a full digital overhaul.

Bridging Traditional Operations and Smart Automation

Our solutions make it easy to document equipment performance and track downtime trends, enabling you to map out your automation journey with confidence. Whether you’re operating in mining, manufacturing, or water treatment, NewElec helps improve equipment efficiency while maximising the value of your existing infrastructure.

What You Get

- Live monitoring of load current, voltage, power, and thermal capacity.

Status feedback on field inputs, interlocks, and trip/alarm conditions. - Event and fault logs with time and date stamps.

- Menu-based relay configuration – no programming required.

- Remote reset and diagnostics for faster fault clearing.

- A user-friendly interface that lets you choose between manual control or automated operation.

- Designed for Electricians. Backed by Engineers.

Our support team works with your electricians and maintenance staff to ensure a smooth transition. You keep your system. You upgrade your capability.

The Smart Way to Modernise Motor Control Systems

Plug In. Power Up. Take Control.

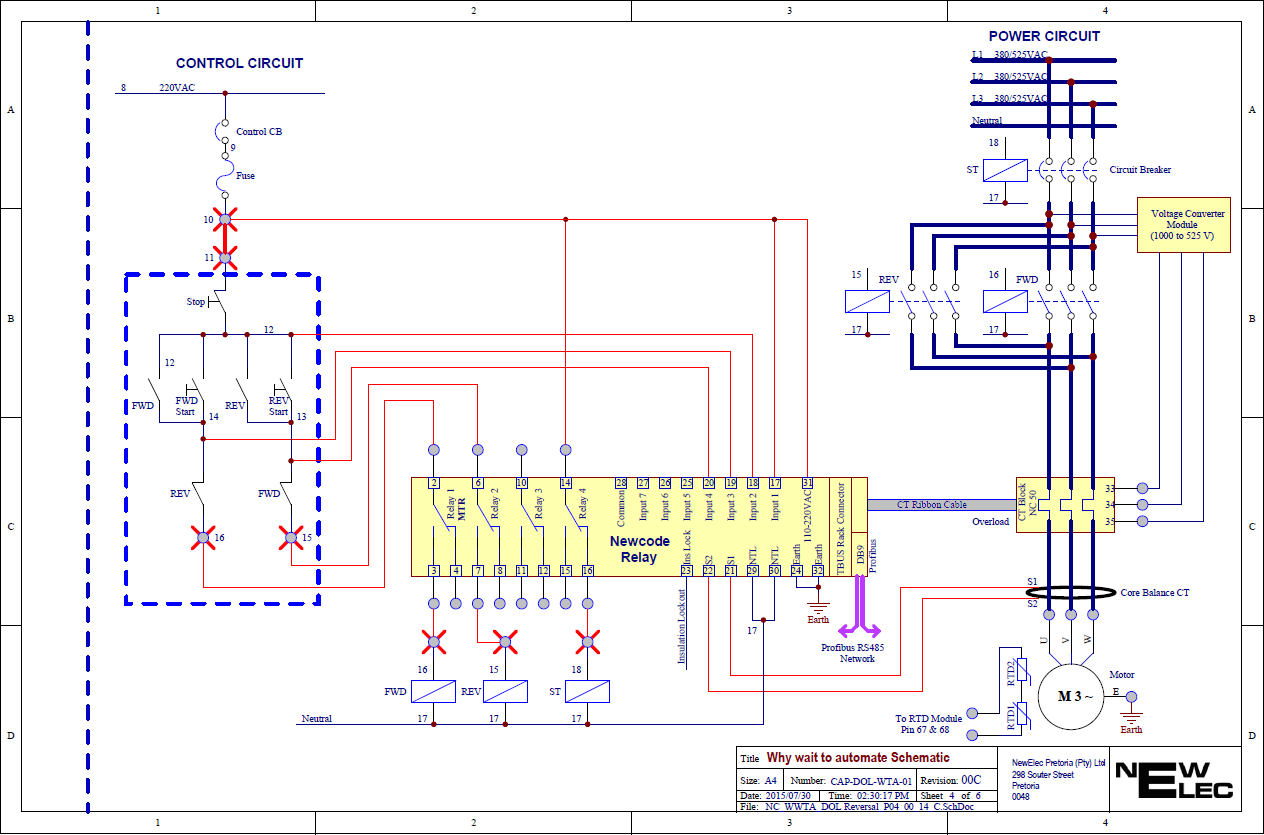

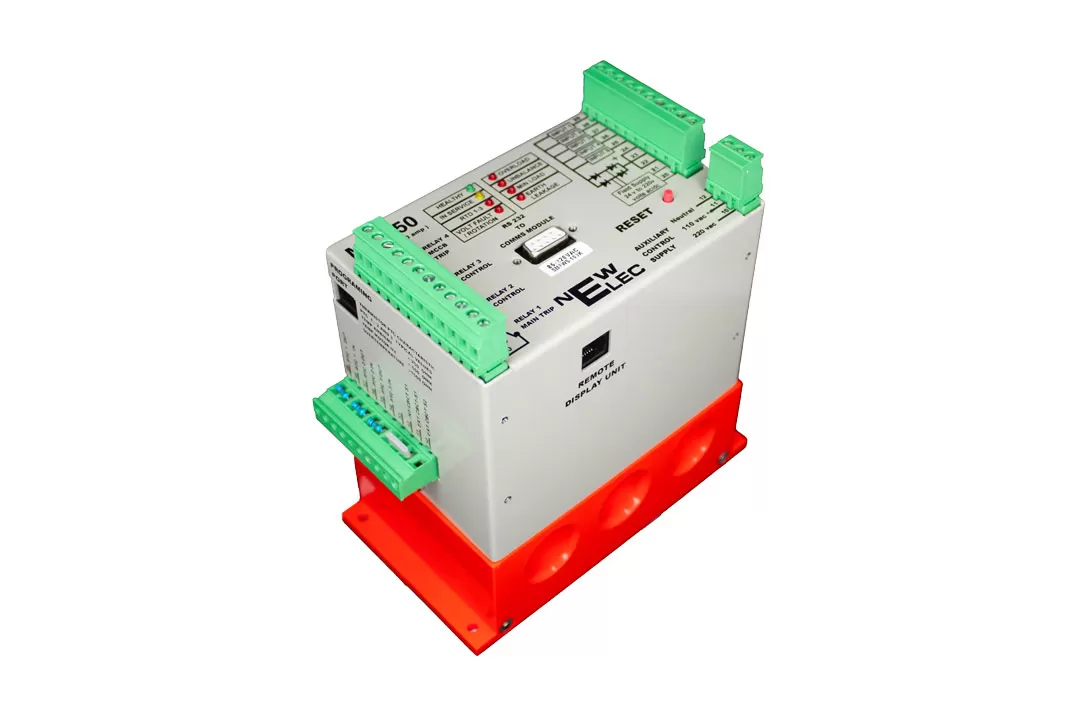

Why Wait to Automate™ transforms your motor control center (MCC) by integrating your current start/stop controls and interlocks into NewElec’s advanced NewCode protection relay. The system connects up to 32 motor cubicles to a single HMI (Human Machine Interface), offering centralised visibility and control, all without changing your basic wiring.

At the heart of the system is a pre-programmed PLC and HMI unit, ready to deploy out of the box. No ladder logic. No software configuration. Just connect, power up, assign addresses, and you’re online.

At NewElec, We understand the realities of industrial environments – tight budgets, older infrastructure, and limited technical resources. That’s why Why Wait to Automate™ is built for quick installation, low disruption, and maximum impact.

MA Series Relays

Upgrade Your MCC Without the Hassle

MA Series Relays

NewElec’s Why Wait to Automate™ makes it easy to modernize your existing motor control centers (MCCs) without needing any PLC programming skills.

NewCode Relays

Future-Proof Industrial Operations Without the Overhead

In demanding industrial environments, ageing infrastructure, limited budgets, and growing safety requirements can make modernisation feel out of reach. NewElec offers a smarter, more practical path forward. With our plug-and-play retrofitting solutions, you can improve visibility, safety, and performance—without the need for full-scale automation or costly equipment replacements.

Smarter Protection and Performance Upgrades—No Full Automation Required

Extends the Life of Ageing Equipment

Delivers Real-Time Energy Insights

Improves Safety and Ensures Compliance

Seamlessly Integrates with Legacy Systems

Enables Safer, Remote Access

Identifies Early Electrical and Load Irregularities

NewElec helps you modernise with confidence—delivering practical, cost-effective solutions that work within your current setup while laying the foundation for future upgrades.

What is “Why Wait to Automate™” and how does it benefit my facility?

“Why Wait to Automate™” is NewElec’s retrofitting approach to bring visibility, protection, and control into existing industrial plants without replacing the entire infrastructure. It allows you to monitor motors, detect faults early, and collect real-time data while keeping your current wiring and control systems intact.

Do I need PLC programming skills to implement your solution?

No. The system is delivered with a preloaded PLC and HMI, so no ladder logic or software coding is required. You only need to connect power, wire the relays, and assign addresses.

What protection features do NewElec relays provide?

The relays include thermal overload protection (class 3 to 35), overcurrent, unbalanced current sensing, breaker-failure detection, earth leakage/fault protection, and short circuit trip capabilities.

How many motor control cubicles can one system monitor, and what kind of display interface is used?

You can monitor up to 32 motor control cubicles through a single touch-screen HMI. The interface allows remote reset, diagnostics, fault logs, status feedback, and switching between manual and automated operation modes.

Can your solution integrate with existing communication protocols and legacy systems?

Yes. The relays support Modbus-TCP, PROFINET, and Ethernet-IP, enabling seamless integration into existing networks without needing to replace your MCC or overhaul wiring.

How it works

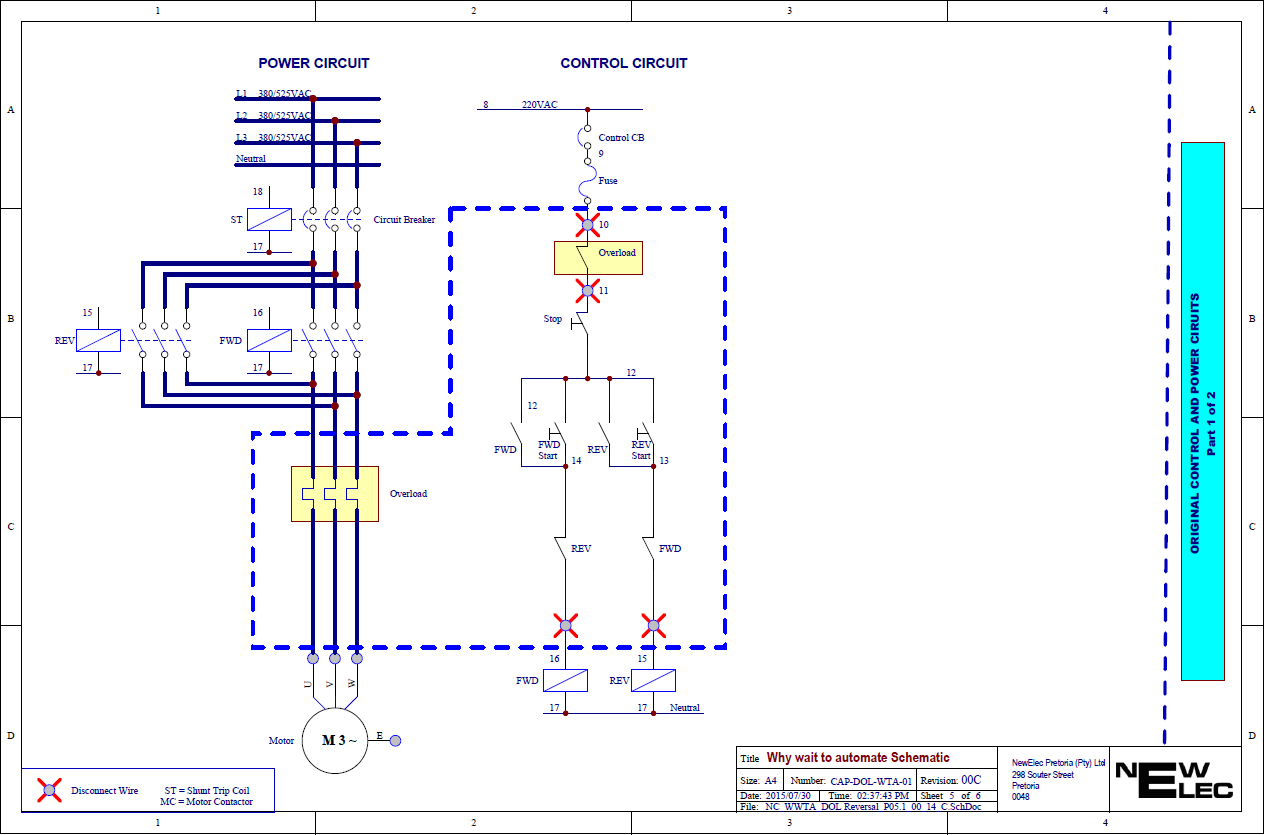

- You connect your existing start/stop controls and interlocks into the I/O terminals of a NewCode protection relay.

- Up to 32 motor control cubicles can be monitored on a single touch-screen HMI.

- The system comes with a preloaded PLC program – no coding or configuration needed.

What you’ll be able to see on screen:

- Actual values like load current, voltage, and thermal load.

- Status of field inputs, interlocks, alarm, and trip flags.

- Time-stamped fault and event logs.

- Remote reset and full control from the HMI.

- Choose between manual or automated operation.

What’s included:

Pre-programmed PLC and HMI unit.

Just connect power, wire the relays, set the addresses – and it’s ready to run. Our team supports you throughout setup, making the upgrade fast, simple, and reliable. You keep your existing wiring – and gain full visibility and control.

Why Choose NewElec?

- Feature-Rich Products – Our relays come equipped with advanced functionalities, including real-time event recording and seamless integration with various communication protocols. These features provide comprehensive protection and control, setting NewElec apart from competitors.

- Long-Term Durability – Designed for a lifespan of 20 to 30 years, NewElec’s products offer long-term reliability and reduced maintenance costs. This durability ensures a solid return on investment and uninterrupted operations.

- Exceptional Support – Our dedicated team provides ongoing guidance and assistance, from initial consultation to post-implementation support. We work closely with clients to tailor solutions that meet their specific needs, ensuring a seamless integration process and optimal performance.

Don’t wait for a shutdown or system failure to upgrade. Why Wait to Automate™ is your practical, scalable, and affordable path to intelligent motor protection and automation. Contact us today to learn how easy it is to bring your MCC into the digital age.