Optimising Heavy Industry Operations with Advanced Motor Protection Systems

At NewElec, we understand the demanding conditions of the Cement, Quarrying, and Mineral Processing industries. From motor control to protection relays, we provide cutting-edge solutions that enhance efficiency, prevent breakdowns, and ensure reliable operations in crushers, kilns, mills, conveyors, and slurry pumps.

Whether you manage cement plants, mineral extraction sites, or quarrying operations, our Motor Protection Solutions are designed to shield critical machinery from failures caused by overload, electrical faults, earth leakage, and excessive wear. Our protection relays and monitoring solutions minimise costly downtimes, enhance equipment lifespan, and improve operational safety.

Why Wait to Automate™

NewElec is transforming the Cement, Quarrying, and Mineral Processing sectors with advanced motor control and monitoring solutions. Our “Why Wait to Automate™” initiative introduces the latest NewCode Relays, which seamlessly integrate with PLC systems to enable real-time monitoring, predictive maintenance, and automation.

Our systems utilize Modbus-TCP, Profinet, Ethernet-IP, and Goose IEC61850 protocols to ensure seamless data exchange across industrial networks. Featuring remote configuration via Bluetooth, vibration monitoring, and motor protection, our KG and KH Relays allow safer and more efficient equipment management with reduced manual intervention.

For cement producers, quarry operators, and mineral processors, NewElec delivers cutting-edge automation solutions that optimise power consumption, improve process efficiency, and ensure long-term reliability.

Contact NewElec Today

Protecting Heavy-Duty Industrial Motors & Pumps in Harsh Environments

The Cement, Quarrying, and Mineral Processing industries operate under extreme conditions, leading to high-stress scenarios for motors and pumps. To prevent failures, our Motor Protection Relays offer comprehensive solutions for:

• Crusher Motors – Prevents overloads, overheating, and phase failures.

• Conveyor Belt Motors – Safeguards against electrical faults and mechanical wear.

• Kiln and Mill Motors – Ensures consistent operation by monitoring voltage fluctuations.

• Slurry and Dewatering Pumps – Protects against cavitation, dry-running, and pressure variations.

Visit our Pump Monitoring Solutions to discover how we can protect critical pumps and motors in high demand industries.

Advanced Earth Leakage and Vibration Monitoring for Industrial Applications

In high-dust, moisture-heavy environments like quarries and cement plants, electrical hazards can lead to equipment failures and safety risks. Our Earth Leakage Protection Systems provide comprehensive coverage against electrical faults and leakage currents that can cause fires or power disruptions. Additionally, our ANSI 38 Bearing Protective Monitoring detects excessive temperature and wear, which are often indicators of vibration issues. Designed for extreme industrial conditions, our IP65-rated durability ensures maximum protection and longevity in the harshest environments.

Learn more about our Earth Leakage Protection Relays and Vibration Monitoring Systems to improve your plant’s safety and efficiency.

Learn more about our Earth Leakage Protection Relays Systems to improve your plant’s safety and efficiency.

Motor Control Systems for Industrial Efficiency

Efficient material handling is essential for cement production, quarrying, and mineral processing. Our protection systems ensure safe and seamless operations by safeguarding critical equipment such as conveyor motors, crusher motors, ventilation systems, and lifting equipment.

Conveyor Motor Protection prevents overloads, ensuring the smooth transport of raw materials.

Crusher Motor Protection enhances safety in crushing and grinding processes.

Fan Motor Protection: To maintain operational efficiency, our fan and ventilation motor protection keeps industrial cooling and ventilation systems running optimally.

Material Handling Cranes: Our crane and lifting equipment protection ensures safe material handling and lifting operations in demanding environments.

“Quiet Champion” in the Cement, Quarrying, and Mineral Processing Industry

Advanced Earth Leakage and Earth Fault Protection

Low voltage and medium voltage Earth Leakage Protection

Vibration Monitoring for Predictive Maintenance

IP65 Rated for Maximum Durability

Field Configurable for Flexibility

Comprehensive Coverage for Critical Equipment

Variable Speed Drive (VSD) Compatibility

Long-Lasting Solutions with Up to a 30-Year Lifespan.

Explore Our Motor Protection Relay Solutions

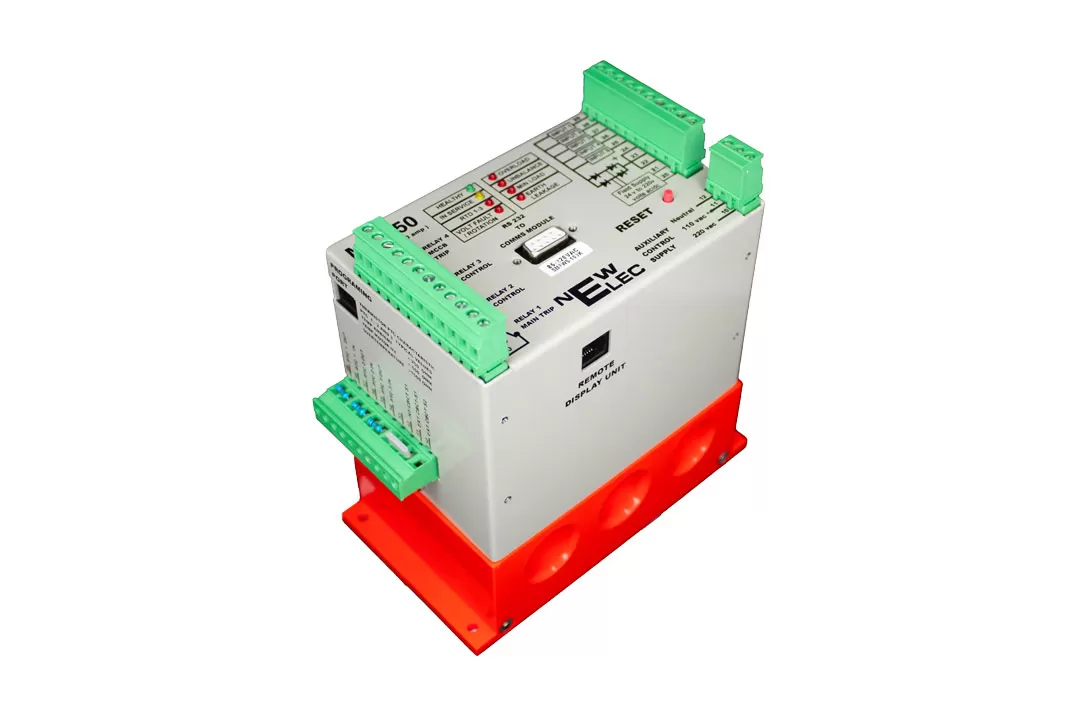

Product – NewCode Relay

Product - MA Series Relays

Product – KE Series Relay

Product - KD Series Relay

Product – KG/KH PQM Relay

Product - 320-327 Series Relay

Product - GA Earth Leakage Relay

Contact NewElec Now!

Why Choose NewElec for Your Industrial Needs?

At NewElec, we specialise in delivering state-of-the-art motor control and protection solutions for the cement, quarrying, and mineral processing industries. Our feature-rich Motor Protection Relays and Earth Leakage Protection Systems improve operational efficiency and reduce long-term costs.

What sets us apart?

Feature-Rich Product:

From Motor Control to Vibration Monitoring and Protection Relays, our products are built with advanced features that set us apart.

Long Lifespan:

Designed to last up to 30 years, our products offer long-term reliability and reduced operational costs.

Liability Management

We help you manage risks effectively, providing expert support to mitigate potential operational issues.

Event and Fault Records:

Our systems include time-stamped, exportable records to help you monitor and manage your operations more efficiently.

Comprehensive Protection:

We provide free Front-End Software for low and medium-voltage motor applications, offering complete protection for your operations.

Commitment to Quality:

Rigorous testing and quality control ensure our products meet the highest standards, giving you confidence in their performance.

Customer Support:

Our relationship with clients goes beyond the sale—we offer ongoing support to ensure our solutions continue to meet your evolving needs.

Exceptional Support and Industry Expertise

Transform Your Industrial Operations with NewElec

Ready to Optimise Your Industrial Operations?

Contact us today to learn more about how NewElec can help you enhance efficiency, optimise power consumption, and protect your most critical assets.

What specific protection does NewElec offer for heavy-load motors in cement and quarrying plants?

Our relays protect against overloads, phase loss / single phasing, imbalance / unbalanced currents, earth leakage / insulation faults, short circuits, locked rotor or jam conditions, undervoltage/overvoltage, and underload (no-load) conditions (e.g. “dry run” detection).

How do these relays help improve plant uptime and reduce maintenance costs?

By continuously monitoring motor health and logging faults and events, they allow early detection of anomalies (e.g. drift in currents, insulation deterioration) before catastrophic failure. This predictive insight helps avoid unplanned downtime.

Can the protective relays integrate with my existing control or SCADA system?

Yes. Many models support communication protocols such as Modbus or Profibus, and can export fault or event data to PLCs or SCADA platforms for centralized monitoring and control.

How many events or fault records can the relays retain for diagnostics?

Some relays in the NewElec line retain up to 2,000 time- and date-stamped event records and up to 60 detailed fault records. This helps maintenance teams trace back issues over time.

Are the relays designed to handle the harsh environmental conditions found in mining, cement, or quarry operations?

Yes, the relays are built to withstand tough industrial environments (dust, vibration, thermal stress). They also incorporate filtering and selectivity to avoid nuisance trips under challenging load or harmonic conditions.